English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski

Have you ever learned about the common processes in the processing of aluminum alloy parts?

2025-04-21

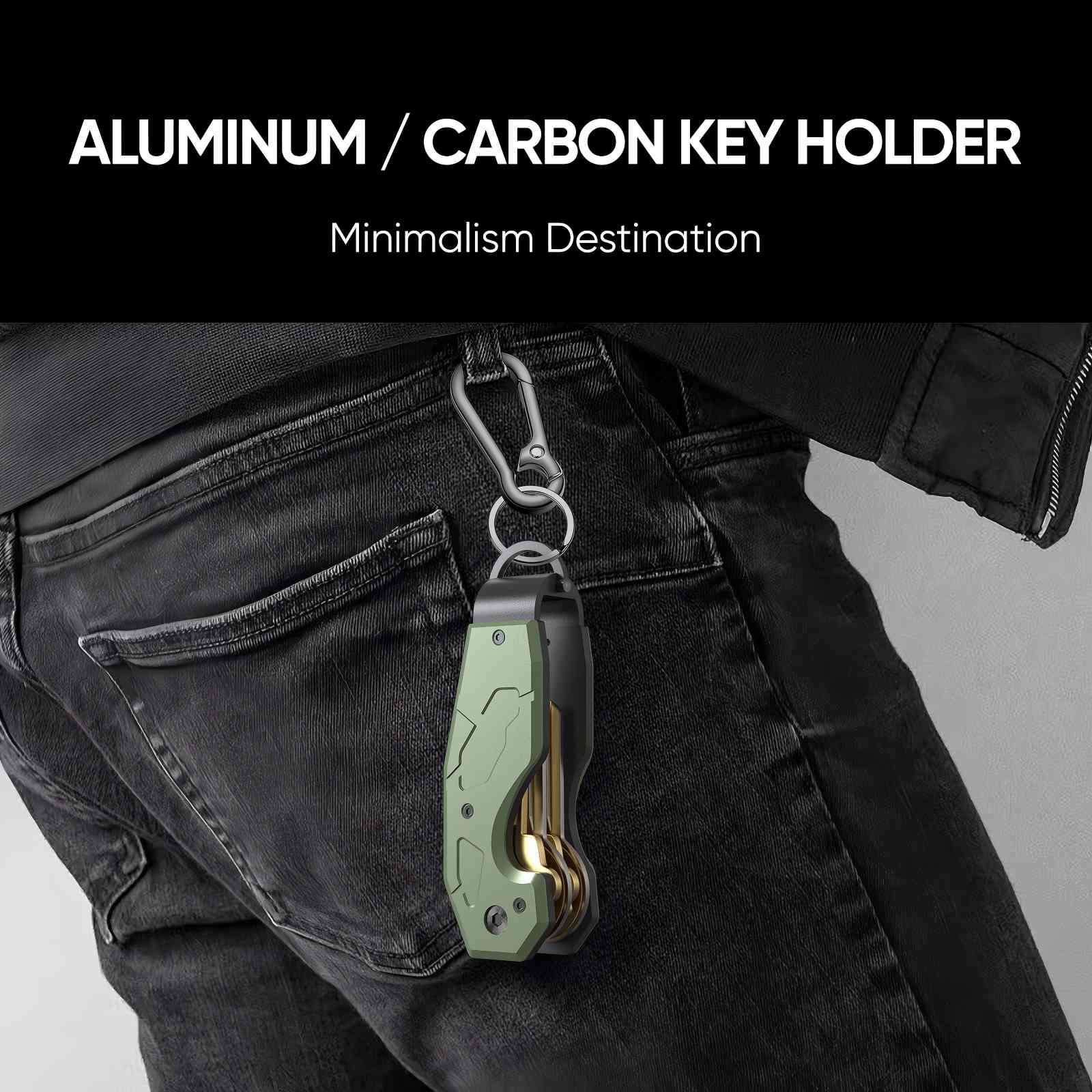

Aluminum alloy features low density, high strength, and corrosion resistance. Its lightness and strength make it widely used in the processing and manufacturing of various parts, such as automotive components and aviation. Aluminum alloy parts are often seen in both technology and daily life. Today, let's share with you how aluminum alloy parts are processed. What are the common processing techniques for aluminum alloy parts?

1. Mechanical processing of aluminum alloy parts, also known as CNC machining, automatic lathe machining, numerical control lathe machining, etc.

(1) Use general-purpose machine tools such as lathes, milling machines, planers, drills and grinders to process mold parts, and then carry out necessary fitter repairs and assemble them into various molds.

(2) For mold parts with high precision requirements, it is difficult to ensure high processing accuracy only by using ordinary machine tools. Generally, precision machine tools are needed for processing.

(3) To make the processing of mold parts, especially those with complex shapes such as punches, concave die holes and cavities, more automated and reduce the workload of fitters in their repair and fitting, it is necessary to use CNC machine tools (such as three-coordinate CNC milling machines, machining centers, CNC grinders and other equipment) to process mold parts.

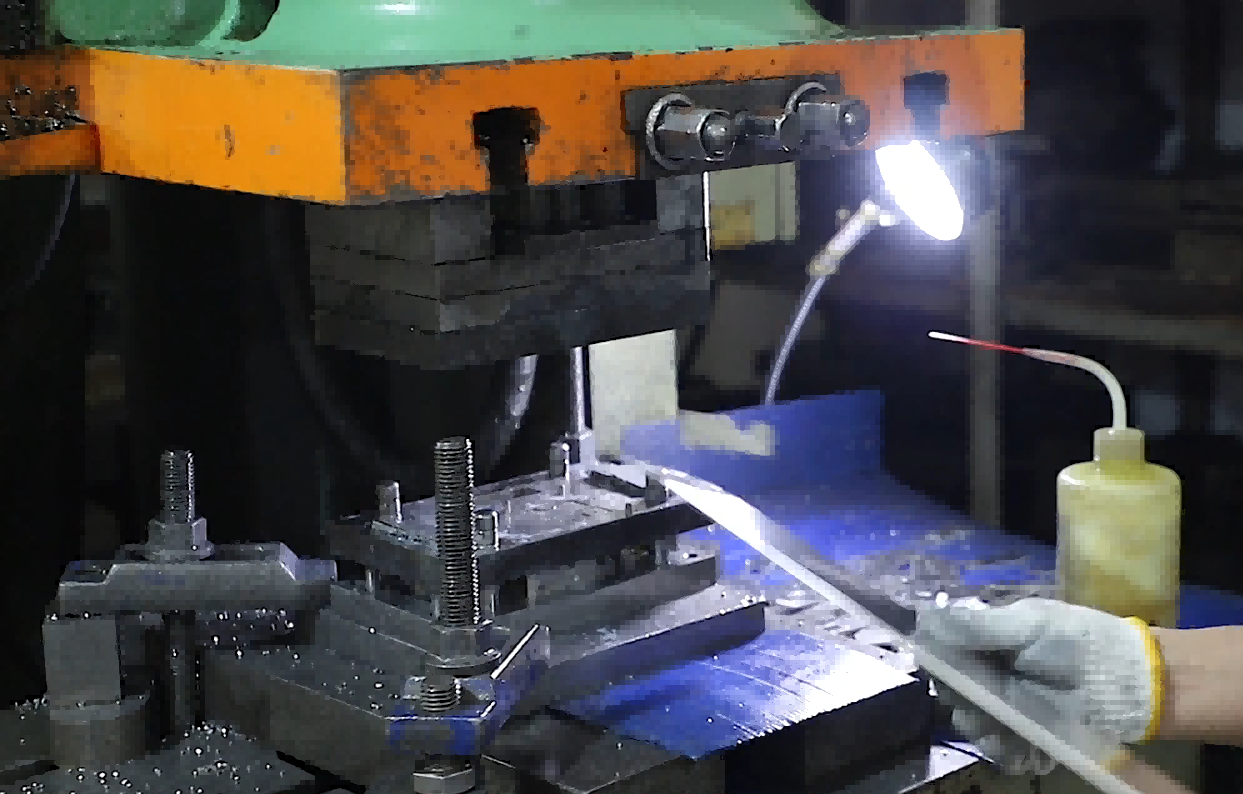

Ii. Stamping Processing of Aluminum Alloy Parts

Stamping is a forming process that uses a press and dies to apply external force to plates, strips, tubes and profiles, etc., causing them to undergo plastic deformation or separation, thereby obtaining workpieces (stamping parts) of the required shape and size. Stamping forming is a production technology that uses the power of conventional or specialized stamping equipment to directly subject sheet metal to deformation force in a die and deform it, thereby obtaining product parts of certain shapes, sizes and properties. Sheet metal, dies and equipment are the three essential elements of stamping processing. Stamping forming is a cold deformation processing method for metals, so it is also called cold stamping or sheet metal stamping, abbreviated as stamping. It is one of the main methods of metal plastic processing.

Iii. Powder Metallurgy of Aluminum Alloy Parts

Powder metallurgy is a technology for manufacturing metal powders and using metal powders (sometimes with a small amount of non-metal powders added) as raw materials, through mixing, shaping and sintering, to produce materials or products. It consists of two parts, namely: (1) Manufacturing metal powder (also including alloy powder, hereinafter collectively referred to as "metal powder"). (2) Materials (referred to as "powder metallurgy materials") or products (referred to as "powder metallurgy products") are manufactured by using metal powders (sometimes with a small amount of non-metal powders added) as raw materials, through mixing, shaping and sintering.

Iv. Precision Casting of Aluminum Alloy parts

Precision casting belongs to special casting. The parts obtained by this method generally do not require further machining. Such as investment casting, pressure casting, etc. Precision casting is a casting method in contrast to the traditional casting process. It can achieve relatively accurate shapes and high casting precision. The more common practice is: First, design and manufacture a mold according to the product requirements (with very little or no allowance left), and then cast the wax by the casting method to obtain the original wax mold. Repeat the coating and sanding processes on the wax mold to harden the shell and dry it. Then, the internal wax mold is melted away, which is called dewaxing to obtain the cavity. Roast the shell to obtain sufficient strength; Pour the required metal materials; After dehulling, the sand is cleared to obtain high-precision finished products. Heat treatment and cold working may be carried out as required by the product.

V. Injection molding of Aluminum alloy Parts

Solid powder is uniformly mixed with organic binder, and after granulation, it is injected into the mold cavity by injection molding machine in a heated plasticized state (~ 150℃) to solidify and form. Then, the binder in the formed blank is removed by chemical or thermal decomposition methods. Finally, the final product is obtained through sintering and densification. Compared with traditional craftsmanship, it features high precision, uniform structure, excellent performance and low production cost. Its products are widely used in industrial fields such as electronic information engineering, biomedical devices, office equipment, automobiles, machinery, hardware, sports equipment, watchmaking, weaponry and aerospace.

We often use the above-mentioned fine craftsmanship to create better products for customers, such as metal keychains, metal wallets, card holders, brackets, etc. In addition to the above-mentioned processing techniques, there are many other processing methods for aluminum alloys. The processing of aluminum alloy parts also involves surface treatment processes, including anodizing, electroplating, etching, etc. Of course, more craftsmanship is manifested in different products; ZA will provide you with more news about metal processing and exquisite products!